|

| January 20, 2015 | Volume 11 Issue 03 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Tips for designing with multi-touch

Using multi-touch in industrial applications enables enhanced human machine interface operation.

By Scott A. Kortier, Sr. Technical Sales, InduSoft, and

Reid Beilke, Industrial PC Product Specialist, Beckhoff Automation

Figure 1: Multi-touch functionality found in mobile devices such as smartphones and tablets is moving to industrial HMIs to improve the operator interface experience.

Multi-touch control is becoming a popular choice for new human machine interface (HMI) designs. Static single-touch HMI displays are becoming a thing of the past as touch technologies in industrial applications move beyond the basics to incorporate the multi-touch functionality found in mobile devices such as smartphones and tablets (Figure 1).

Today's multi-touch technology enables pinch, zoom, rotate, flick/swipe, and other functions. When designing for these multi-touch control functions, the application software and hardware must be carefully selected.

The best HMIs are designed for ease of use by all operators on the plant floor. Optimized operation should leverage modern technology advances and positively affect every aspect of the HMI -- from the way it looks, to the way it behaves, to the way it can connect the user to live data from the plant and to live support from the machine builder or equipment vendor. The interface should reduce or eliminate the need for training because of its intuitive design.

A major new development that enables enhanced user-friendly HMI hardware is multi-touch technology. Well beyond a simple "cool factor," multi-touch enables easier and more intuitive access to detailed plant information, such as scrolling through detailed machine views, with pop-ups indicating important updates or problem areas.

Users can pinch and zoom into specific machine modules for more information on a targeted area. This is a much more user-friendly experience than a traditional single-touch interface, which requires far more time spent clicking through different machine views and menu options.

Choosing the right multi-touch experience

OEMs, custom equipment suppliers, and other end users with graphical display requirements often use simple single-touch screen displays. These HMI displays are the face of the machine and are a big part of the operator experience, and using older touch technologies can impart the wrong message.

One solution is to create graphical displays using custom code, such as VB.net, but this often results in overly complex applications requiring a large amount of difficult-to-support custom code.

Another solution is to use off-the-shelf HMI software, such as InduSoft's Web Studio (www.indusoft.com), with multi-touch functionality built in. But care must be taken to ensure the proper application software and hardware is used, as shown in Table 1, a multi-touch selection check list.

Table 1: Multi-touch selection check list

1. Operating system supports multi-touch

2. Hardware supports multi-touch

3. HMI software supports multi-touch

4. Touch technology is appropriate for application

5. Multi-touch functions are easily selectable

6. No custom code required for multi-touch functions

7. Support for five or more points of touch

Multi-touch points

Multi-touch HMI hardware and software are available from a number of suppliers and have many functions, as listed in Table 2 and discussed below.

When designing a multi-touch application, the hardware touch technology is an important consideration. For example, touching two locations on a resistance-sensitive touch screen may average the two touch points, selecting the touch cell between the two points. Multi-touch panels with projective capacitive touchscreen technology are a better choice as they have high touch-point density that enables accurate, safe, and jerk-free operation, even in minute steps.

Industrial displays optimized with multi-touch technology, such as those from Beckhoff (www.beckhoff.com), offer up to five simultaneous points of touch on the screen at any time. These displays are purposefully designed for industrial use and feature robust, stable construction with protection ratings up to IP 65.

Displays are available in multiple formats such as 16:9, 5:4, 4:3, as well as versions in landscape or portrait orientation (Figure 2). In addition, screen sizes and resolutions from 7 in. (800 x 400 resolution) up to 24 in. (1920 x 1080) are available, with numerous variants in between for maximum flexibility for the application.

Figure 2: Multi-touch displays are available in landscape or portrait orientation, allowing users to select the best technology for their particular application.

Table 2: Multi-touch common functions

1. Zoom into graphic, details appear or become clearer

2. Rotate knob using multiple touches

3. Swipe to quickly move through trend data

4. Swipe to change pages or screens

5. Un-pinch to wide screen to display more content

Software is also an important consideration in multi-touch applications. The ability to use multi-touch functions should be built into the software with simple selection of functions such as pinch, zoom, and rotate. InduSoft Web Studio enables these features with just a simple checkbox.

Implementation is greatly simplified when multi-touch technology is built in to the application software and the hardware.

Experiencing the benefits

Even with simple HMI applications, multi-touch can provide significant advantages when compared to single-touch, such as faster operator interaction, easier navigation among screens, and quicker access to data.

On more complex HMI applications for larger machines, assembly lines, and processes, there are many advantages when using a properly designed multi-touch graphical display as listed in Table 3 and discussed below.

Multi-touch HMI is a key enabling technology in the area of troubleshooting and support. For example, when scrolling through a help manual within the HMI, there's no need to find the scroll bar, because users can just swipe or grab the document and rapidly navigate to the desired section.

In many instances, there's no longer a need for problems to be resolved the old-fashioned way by opening up the electrical cabinet, logging into the controller, and then struggling through data tables to find information.

Instead, a multi-touch HMI can visually show a wealth of diagnostic information, such as production data and measurements relating to the health of equipment. Parameters like temperature, vibration, energy use, and others can also be monitored.

The multi-touch interface gives machine operators an intuitive way to view information. As users of technology become entrenched in multi-touch interaction with dynamic interfaces through the use of devices such as smartphones and tablets, multi-touch will grow from its status as a strong preference to become, eventually, a requirement for industrial applications.

Table 3: Multi-touch advantages

1. Operator experiences faster interaction

2. Second nature to new operators

3. Better control of large screens

4. Requiring multiple touches can eliminate inadvertent single-touch errors

5. Operator awareness and alertness often improved

Applying multi-touch

A packaging line is often comprised of many types of machines, including cartoning, case/tray forming, conveyors, form fill and seal, labeling, and wrapping. Each machine often has its own HMI to operate a particular local process, but complete packaging lines are often complex, taking up considerable floor space.

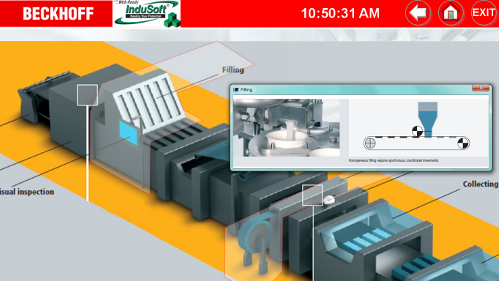

Using multi-touch, operators or maintenance personnel at a local machine can zoom out to view the status of the entire packaging line and then pinch, swipe, and pan to different machines (Figure 3). Rather than trying to find the + and - buttons, and understand if they are for zoom features or not, the user simply uses pinch or un-pinch to zoom in or out. Saving 30 seconds here and there over the span of a shift by using multi-touch can eliminate several minutes of downtime -- and potentially save thousands of dollars.

Figure 3: Using a multi-touch HMI on this packaging line application allows operators to quickly move from an overview of the entire line to a close-up of a single machine.

The popularity of smartphones and tablets has shown that multi-touch provides a much more intuitive interface. Even though touch screens have been available for more than 20 years on HMIs, the recent influx of devices with multi-touch has leapfrogged single-touch technologies.

Multi-touch features such as pinch to zoom, pan, and rotate offer a very familiar user interface that is now expected by the current generation of users. This improved interface can result in a higher quality product produced at a lower cost with higher throughput.

Published January 2015

Rate this article

View our terms of use and privacy policy